Popcorn Caramel Coating Machines

Download PDF

RoboLabs caramel coating machines consist of two key parts – the kettle where caramel syrup is cooked and mixed with popcorn and mesh–belt conveyor, where caramel corn is cooled and separated.

Operator is just responsible for loading all necessary components and launching the process.

As a result you will always have a consistent product quality. It’s all in 15 minutes the batch of

caramel popcorn is ready.

New RoboLabs Showroom in UAE, DUBAI is open

RoboLabs and our long lasting partner Equip.me have opened brand new showroom in UAE, Dubai Jebel Ali Free Zone!

The Grand event took place on April 24-26. More than 50 guests from Mena region have joined us in culinary show, food tasting and equipment showcasting.

The warehouse with machinery and spares is open 365 days! Our engineers will present you the equipment and provide with local service. RoboLabs and its eqclusive equipment are now avaliable for purchase, testing and delivery from UAE for dealers and clients. Contact us to book a demo!

Caramel Coating Machine RoboSugar 10

Technical specifications

- Output - up to 14 kg/hr (30 lbs/hr)

- Maximum load - 3,5 kg (7,5 lbs)

- Kettle capacity - 37,5 L (10 gallons)

- Voltage - 230 V

- Power - 5500 W

- Dimensions - 1650х810х1500 mm

- Weight - 160 kg

Documents

- OPERATING MANUAL ROBOSUGAR 10 - Download

RoboSugar makes caramel and coats popcorn with it automatically.

Caramel cooking and coating take place in the kettle. The operator is

only responsible for loading popcorn into the kettle and dumping of

caramel coated popcorn on the mesh-belt conveyor.

When popcorn is coated operator dumps popcorn on the mesh where it is separated and cooled automatically with all the scrap and small fragments falling through the mesh. When coating is over caramel popcorn goes right into the case.

When popcorn is coated operator dumps popcorn on the mesh where it is separated and cooled automatically with all the scrap and small fragments falling through the mesh. When coating is over caramel popcorn goes right into the case.

Caramel Coating Machine RoboSugar Auto 10

Technical specifications

- Output - up to 14 kg/hr (30 lbs/hr)

- Maximum load - 3,5 kg (7,5lbs)

- Kettle capacity - 37,5 L (10 gallons)

- Voltage - 230 V

- Power - 5500 W

- Dimensions - 1650х810х1500 mm

- Weight - 170 kg

Documents

- OPERATING MANUAL ROBOSUGAR 10 AUTO - Download

RoboSugar Auto 10 makes caramel coating maximally automatic, providing consistent product quality, since the human factor is completely out of the process.

Caramel coating takes place in the kettle.

As soon as popcorn is fully caramelized, it is dumped onto the mesh belt where it is separated and cooled with all the scrap and small fragments falling through the mesh. When coating is over caramel popcorn goes right into the case.

Caramel coating takes place in the kettle.

As soon as popcorn is fully caramelized, it is dumped onto the mesh belt where it is separated and cooled with all the scrap and small fragments falling through the mesh. When coating is over caramel popcorn goes right into the case.

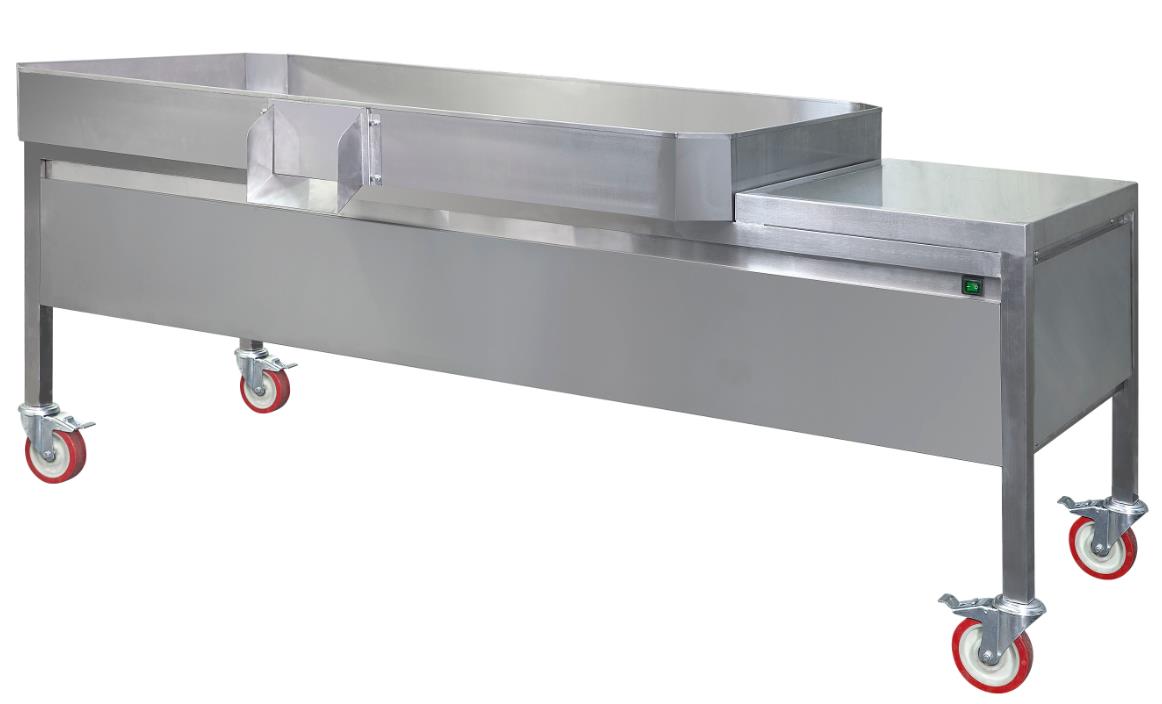

Caramel Coating Machine RoboSugar Auto 20

Advantages

- Enhanced productivity

- Compared to its predecessor, Caramelizer RoboSugar Twin Auto 20 is fully automatic and double in its output - up to 35 kg/h (75 pounds) . Perfect solution for gourmet popcorn producers and concessionaries

- Always consistent product quality

- A 75 liters (20 gallons) aluminum kettle equipped with a tubular heating element provides uniform and consistent heating without any burning of cooked caramel

- Easy maneuverability

Technical specifications

- Output up to - 35 kg/hr (75 lbs/hr)

- Kettle capacity - 75L (20 gallons)

- Voltage - 230/400 V

- Power - 13000 W

- Dimensions - 2100x900x1500mm

- Weight 250 kg

Documents

- OPERATING MANUAL ROBOSUGAR TWIN AUTO 20 - Download

Caramelizer RoboSugar 20 continues the range of RoboSugar models, providing a variety of innovative solutions for gourmet popcorn production.

Caramelizer RoboSugar 20 needs minimum operator’s involvement.

An operator only puts all the necessary ingredients into the kettle plus popped corn into the container.

Thanks to innovative engineering solutions, the conveyor cooling mesh and drum separate and cool even thick layered caramel.

Caramelizer RoboSugar 20, mounted on locking swivel casters is very maneuverable and can be easily relocated

Caramelizer RoboSugar 20 needs minimum operator’s involvement.

An operator only puts all the necessary ingredients into the kettle plus popped corn into the container.

Thanks to innovative engineering solutions, the conveyor cooling mesh and drum separate and cool even thick layered caramel.

Caramelizer RoboSugar 20, mounted on locking swivel casters is very maneuverable and can be easily relocated

Caramel Coating Machine SugarLips 10

Technical specifications

- Output - up to 14 kg/hr (30 lbs/hr)

- Kettle capacity - 37,5 L (10 gallons)

- Voltage - 400 V

- Power - 5000 W

- Dimensions - 760x500x900 mm

- Weight - 50 kg

Documents

- OPERATING MANUALSUGARLIPS 10 - Download

SugarLips 10 cooks caramel and coats popcorn with it.

The key part of the machine is a stainless steel kettle where cooking and coating takes place.

Caramel Coating Machine SugarLips 20

Technical specifications

- Output - up to 35 kg/hr (75 lbs/hr)

- Kettle capacity - 70 L

- Voltage - 400 V

- Power - 12200 W

- Dimensions - 560x890x1150 mm

- Weight - 75 kg

Documents

- OPERATING MANUAL SUGARLIPS 20 - Download

SugarLips 20 cooks caramel and coats popcorn with it.

The key part of the machine is an aluminum kettle where cooking and coating takes place. Compared to SugarLips 10 Sugar lips 20 has twice bigger output - up to 35 kg/hr

Caramel Coating Machine SugarLips 100

Advantages

- SugarLips 100 fits 260 liters of popcorn.

- Kettle is made of stainless steel.

- Handle for caramel popcorn unloading.

Technical specifications

- Power – 32 000 W

- Weight – 285 kg

- Dimensions- 1080x1410x2000 mm

Documents

- SugarLips 100 with Cooling Table dimension drawing - Download

- SugarLips 100 User Manual (400 V) - Download

- Cooling Table CKPMX-03M2 User Manual (230 V) - Download

- SugarLips 100 User Manual (208 V) - Download

- SugarLips 100 Technical Manual (208 V) - Download

- SugarLips 100 Wiring Diagram (208 V) - Download

SugarLips 100 is the biggest caramelizer with a capacity up to 100 kg of caramel corn.

It cooks caramel and coats pre-popped popcorn with it.

The caramelizer could be used as a single standing equipment or included as part of caramel popcorn manufacturing line.

Additionally could be supplied with the cooling table for manual cooling and separation. Cooling table is equipped with fan for caramel popcorn cooling.

Cooling surface of the table is 2350х1500 mm.

The table surface perforation is 8 mm.

The caramelizer could be used as a single standing equipment or included as part of caramel popcorn manufacturing line.

Additionally could be supplied with the cooling table for manual cooling and separation. Cooling table is equipped with fan for caramel popcorn cooling.

Cooling surface of the table is 2350х1500 mm.

The table surface perforation is 8 mm.