|

Vortex Popcorn™ machine Robopop® is a new type of machines, which pops kernels using revolutionary technology.

|

Robosugar is revolutionary machine for caramel popcorn coating.

|

"Air" or "wet" popcorn

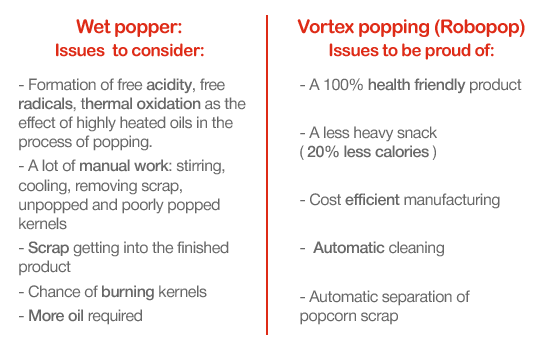

Up to now the world has known (and has been using) two classic technologies for popping corn — popping in high heated oil or in hot air stream. Now that we have Robopop®, here’s a new technology — Vortex.

Тypical representatives of the "oil" type

Let us review the traditional ways, their pluses and minuses. It is common knowledge that corn popped in oil is always a delicious crunchy movie style snack. It happens because popcorn, having been popped, immediately leaves the kettle without having been subjected to high temperature for a long time.

The disadvantage of this method is its expensiveness. Compared to hot air popping, it uses a lot of oil, 30-50% more. Oil burns out, stays on kettle walls, evaporates, smokes, And in general it is far from being a healthy way of popping, sharing all the problems pertaining to all deeply fried foods.

That is why pre-poppers prefer hot air processing; it makes high volume production more economical. And this is advantage #1.

Typical representatives of the "air" type

The second advantage – it is more technological and can be fully automatic. But as said earlier, due to puffer's constructive features, most of popped corn stays rather long inside the chamber at 200 – 240*C turning into chewy styrofoamy stuff. Further oil flavoring and seasoning of hot air popped corn makes it taste better, but compared to popped in oil corn, there is no comparison.

Vortex technology

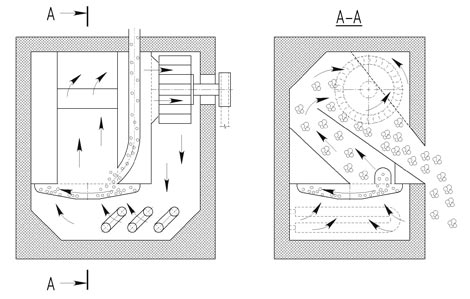

Vortex popping, used in Robopop® equipment, conveniently combines all the advantages of both methods, being free from all the drawbacks. How does it happen? Very simple! Hot air Vortex, picking up corn kernels, swirls them up and away from the heated zone, literally in milliseconds, without giving them the chance to stay under high temperatures for a long time. As a result, after having been oil flavored and seasoned, which is done in one step in the same machine, popcorn tastes no different from a movie style crunchy delicious treat. Further cheese or caramel coating turns it into a gourmet snack.

Right from the moment, when the first Robopop® Mark3 model showed up on the market, our key customers - movie theaters - immediately appreciated the advantages of hot air vortex method.

At present, we are manufacturing a new Robopop® 60 product line (Mark 4), which will permit to make two types of popcorn: salty and basic (for further caramel coating) to better meet all the movie theater concession requirements.

Besides, Vortex technology easily turns into automatic technology: most Robopops® are either fully or semi-automatic requiring minimum involvement of operators. And lastly, like regular hot air popping, vortex technology saves 30 percent oil.

New generation - Robopop® 60

Right from the moment, when the first Robopop® Mark3 model showed up on the market, our key customers — movie theaters — immediately appreciated the advantages of hot air vortex method.

At present, we are in the process of making a new Robopop® 60 product line (Mark 4). This line will permit to make two types of popcorn: salty and basic (for further caramel coating) to better meet all the movie theater concession requirements.

As is known, most movie theater audience is families with kids. Contemporary parents are very selective in what they buy for their kids. Robopopped corn meets the highest standards: it is a natural, delicious crunchy snack, full of flavor, aroma, with a very small content of fat

Let us listen to what Kronverk Cinema says, one of the first Robopop® Mark 3 buyers. (recorded in 2012)

For those who are concerned with calories and overheated oils health hazards, we suggest a technology that takes care of that and at the same time makes production very cost effective. Automatically regulated, oil application cuts both the caloric content of the snack and its cost.

Figure out how much money you may save following this link!

If you would be interested in partnership and the equipment international promotion, fill out the application “Become our dealer” today and our specialists will contact you shortly.

A less calorie snack (20% less calorie)