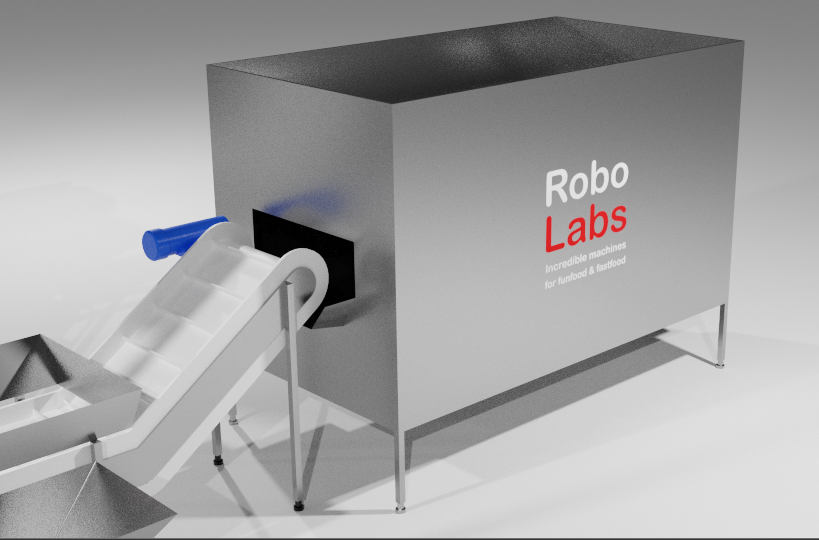

Industrial Popcorn Equipment RoboFactory

Download PDF

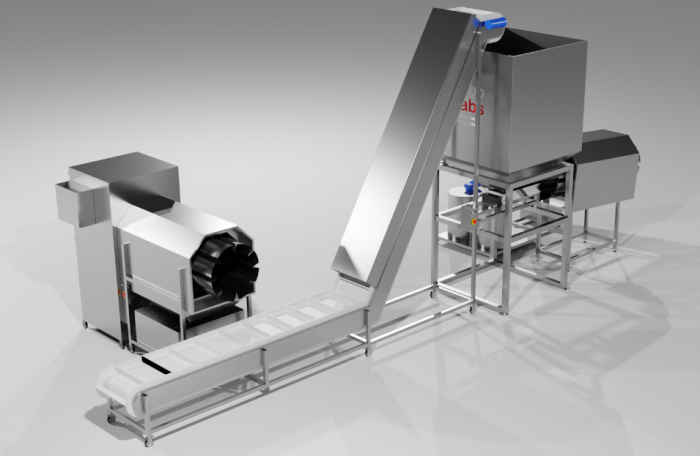

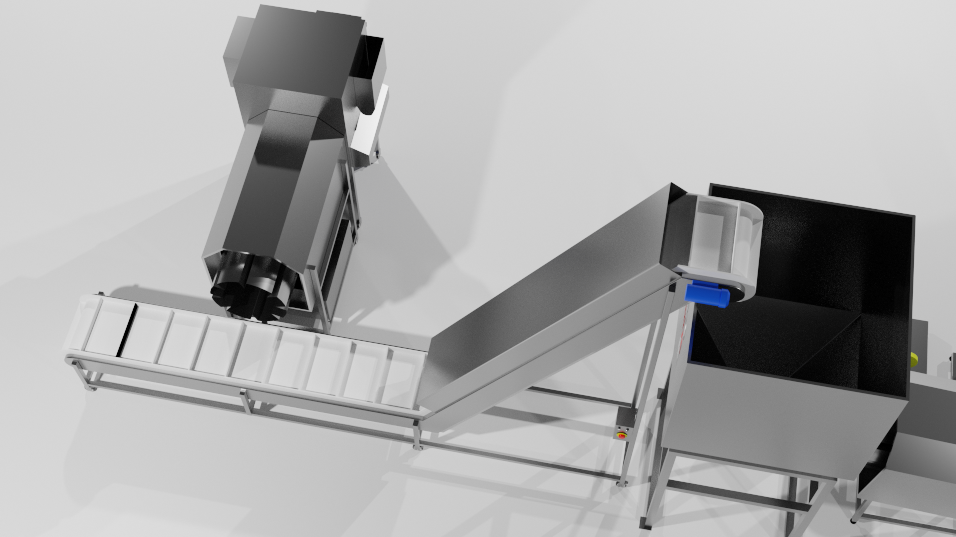

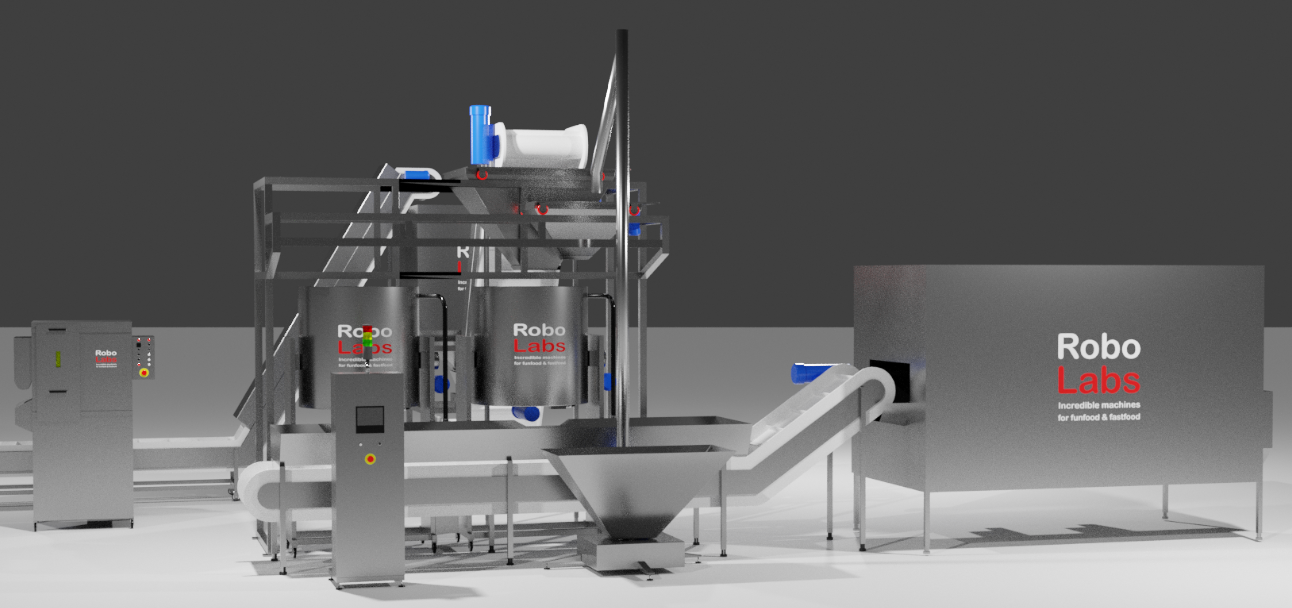

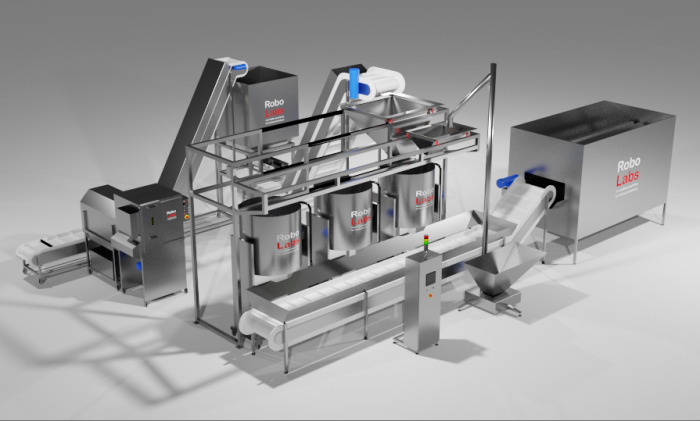

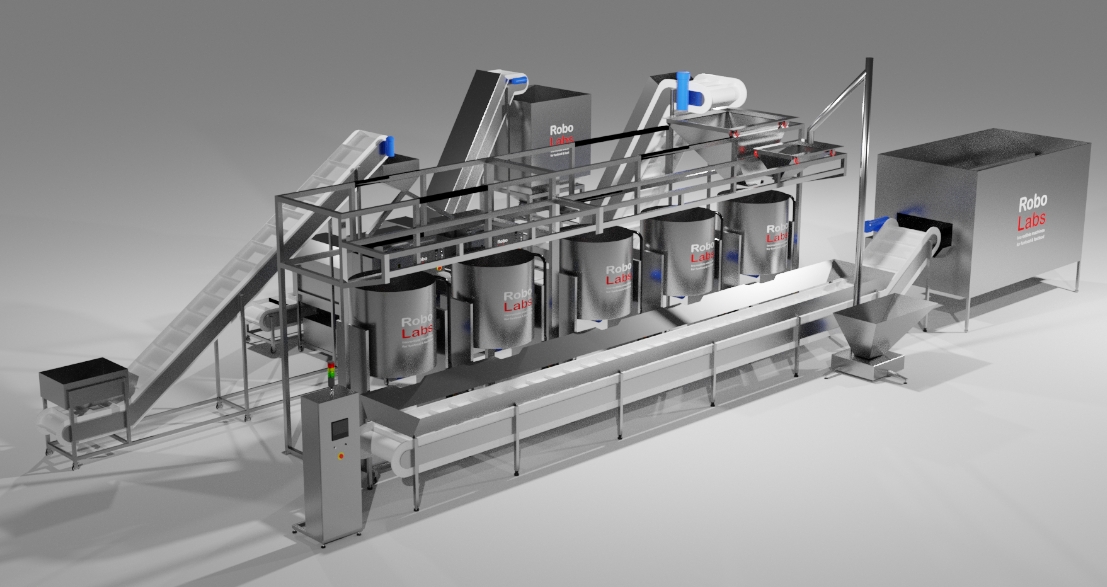

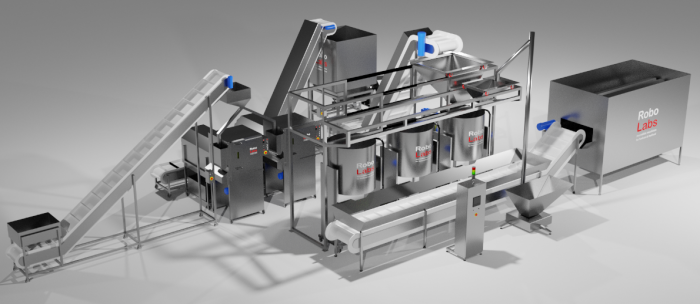

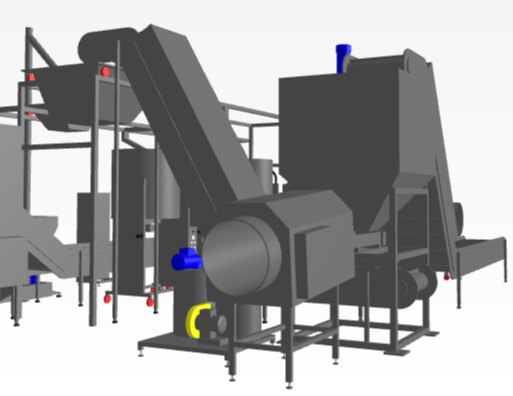

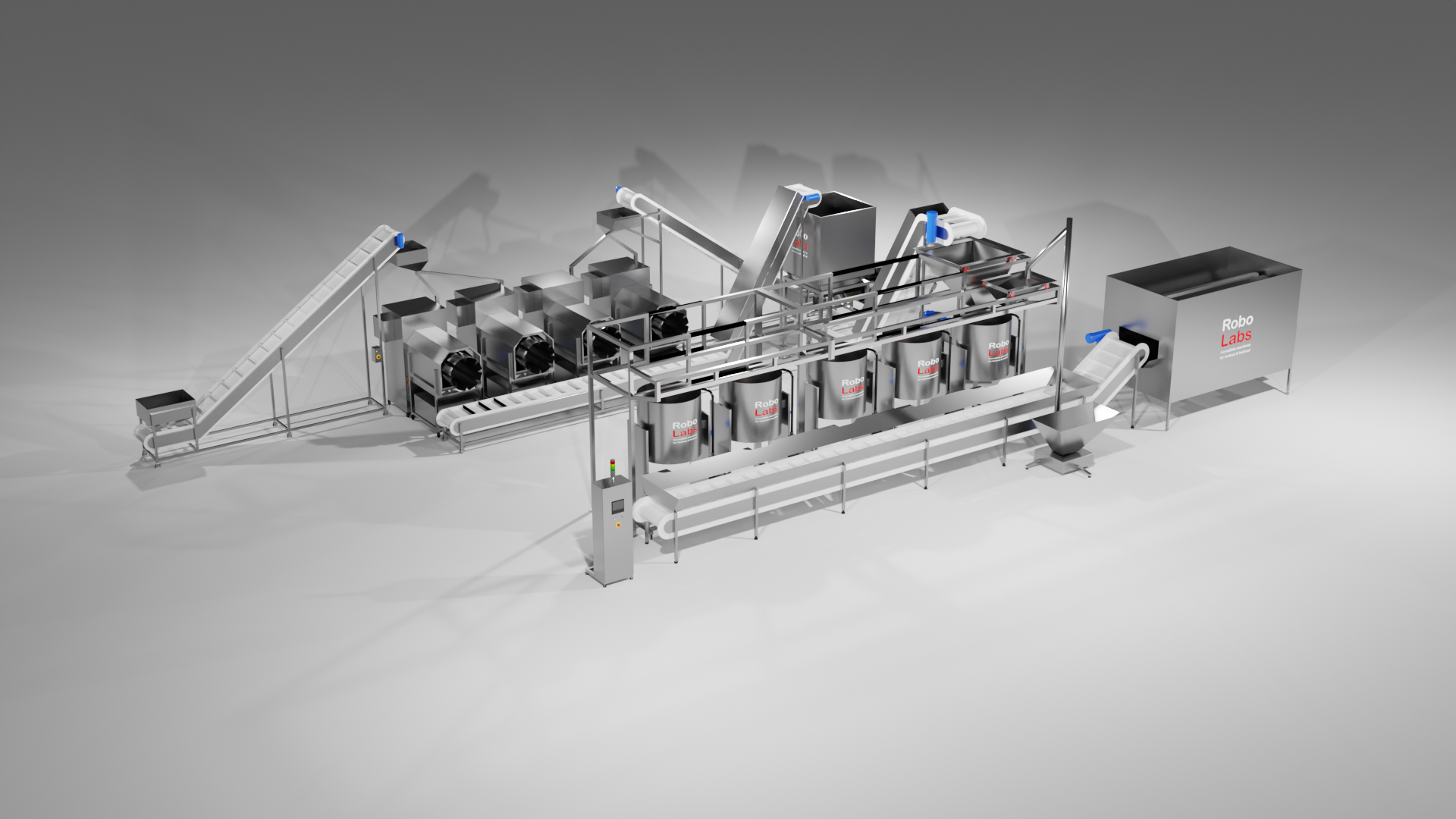

RoboFactory is fully automated industrial line for savory and caramel coated popcorn production.

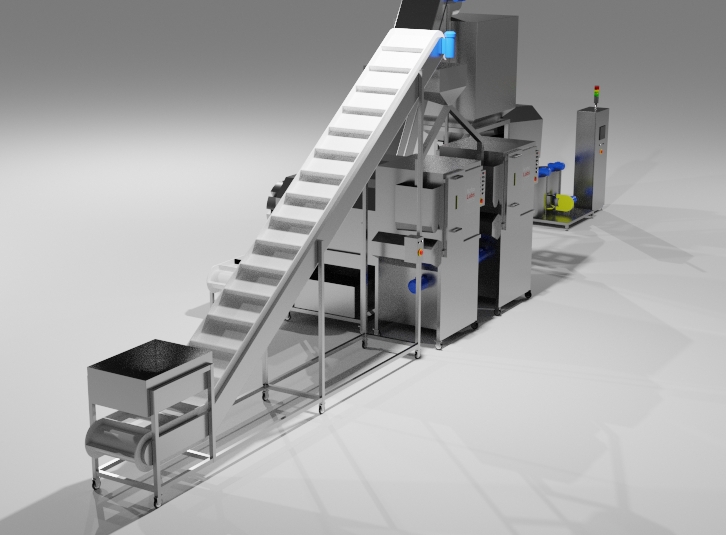

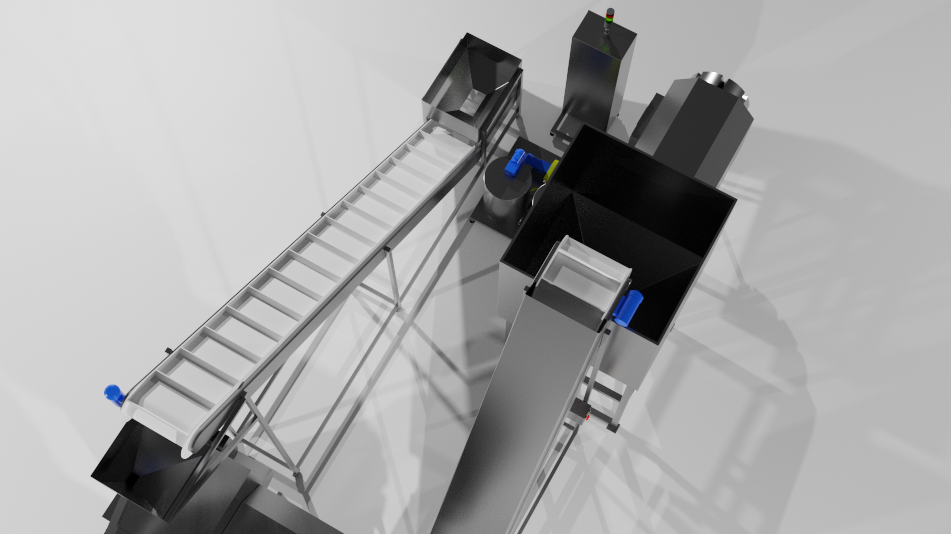

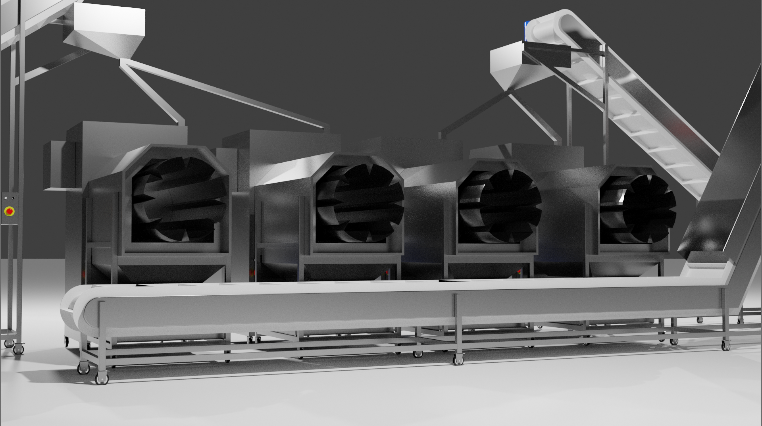

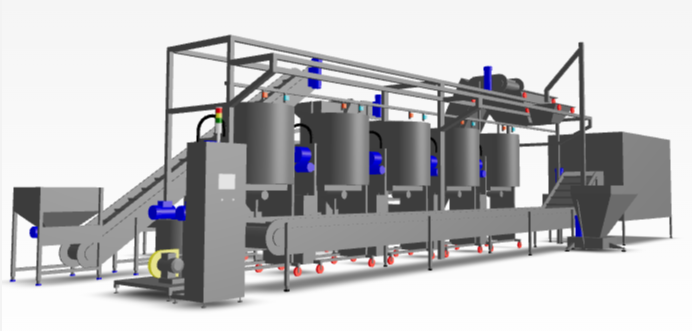

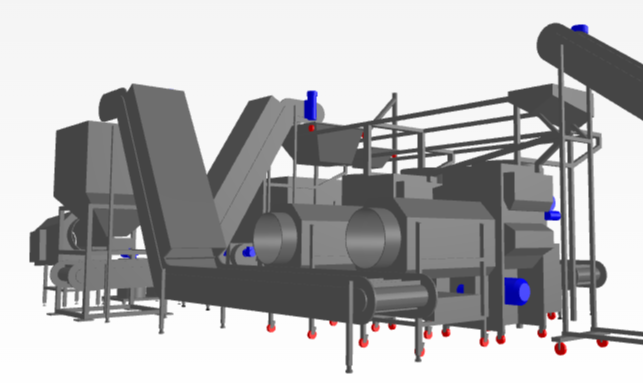

RoboFactory 100 kg/h Salty/Cheese/Spicy Popcorn

Advantages- Highly automated - one touch screen

- Duplication of controls on each element

- Highly reliable

- Maintainability

- AISI304 food-grade stainless steel

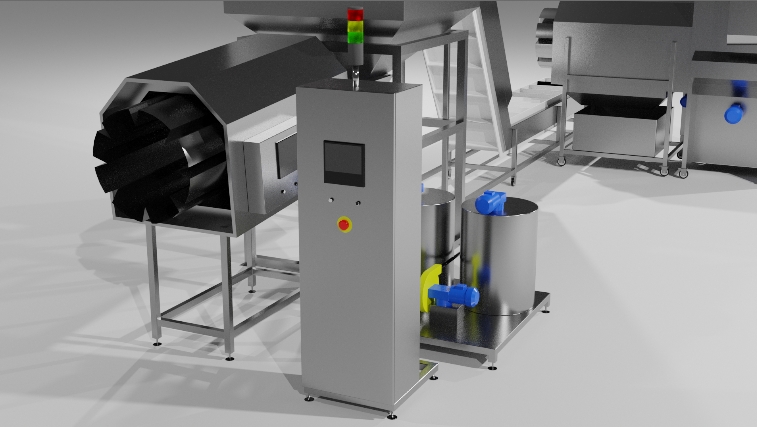

- Easy to control - the entire line as modules on the touchscreen, and the settings of each module are easy to see and adjust Protection against misuse - the RoboFactory 100 is equipped with sensors and a sound / light alarm system that reports abnormal operating modes

- RoboFactory 100 is a turnkey cheesy/savory popcorn factory with a capacity of up to 100kg (220lbs) of popcorn per hour.

At the entrance, you pour raw materials: popcorn grains, salt, butter, cheese powder, and spices. As a result, you get the finished product without any extra effort.

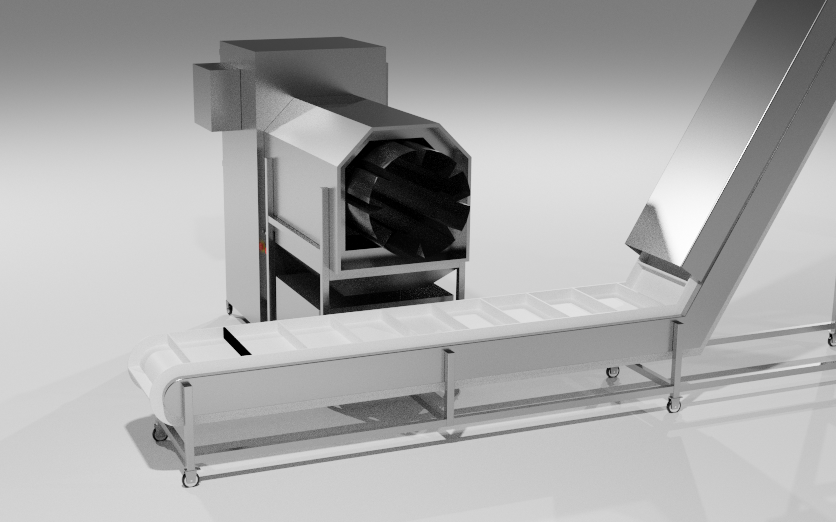

The production line is fully automated, controlled from a single touchscreen, 1 operator is enough for maintenance. Using the Robopop220 vortex popcorn machine allows you to refuse the "wet method" of opening the maize kernels - popcorn grains are not fried in oil (there are no trans fats or carcinogens). The product is healthier and less high-calorie.

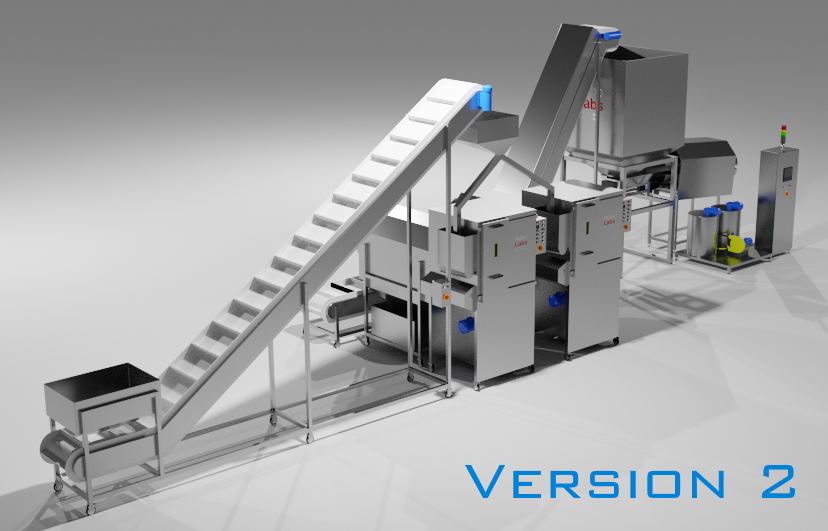

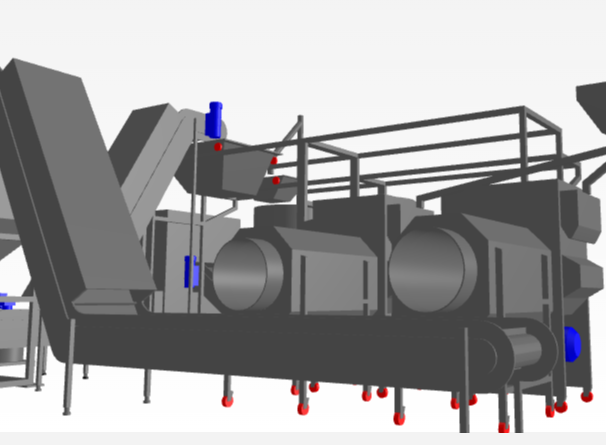

The oil is used only at the last stage to give the taste of the finished product, which also allows you to significantly reduce the cost and save on oil. Your premises will be cleaner - no need to remove oil cinders from the surfaces of equipment, cabinets, or floors. It is much easier to clean the popcorn equipment at the end of the shift. Easy to upgrade to RoboFactory 200RoboFactory 200 kg/h Salty/Cheese/Spicy Popcorn

Advantages- Highly automated - one touch screen

- Duplication of controls on each element

- Highly reliable

- Maintainability

- AISI304 food-grade stainless steel

- Easy to control - the entire line as modules on the touchscreen, and the settings of each module are easy to see and adjust Protection against misuse - the RoboFactory 200 is equipped with sensors and a sound / light alarm system that reports abnormal operating modes

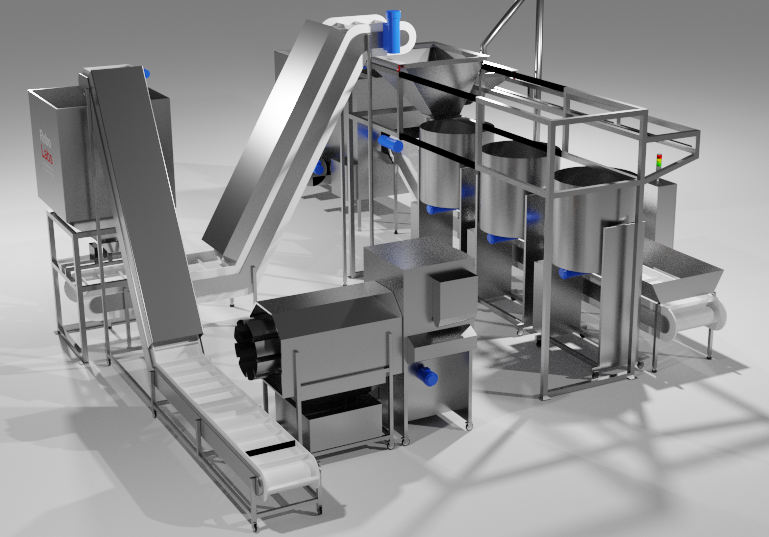

- RoboFactory 200 is a turnkey cheesy/savory popcorn factory with a capacity of up to 100kg (220lbs) of popcorn per hour.

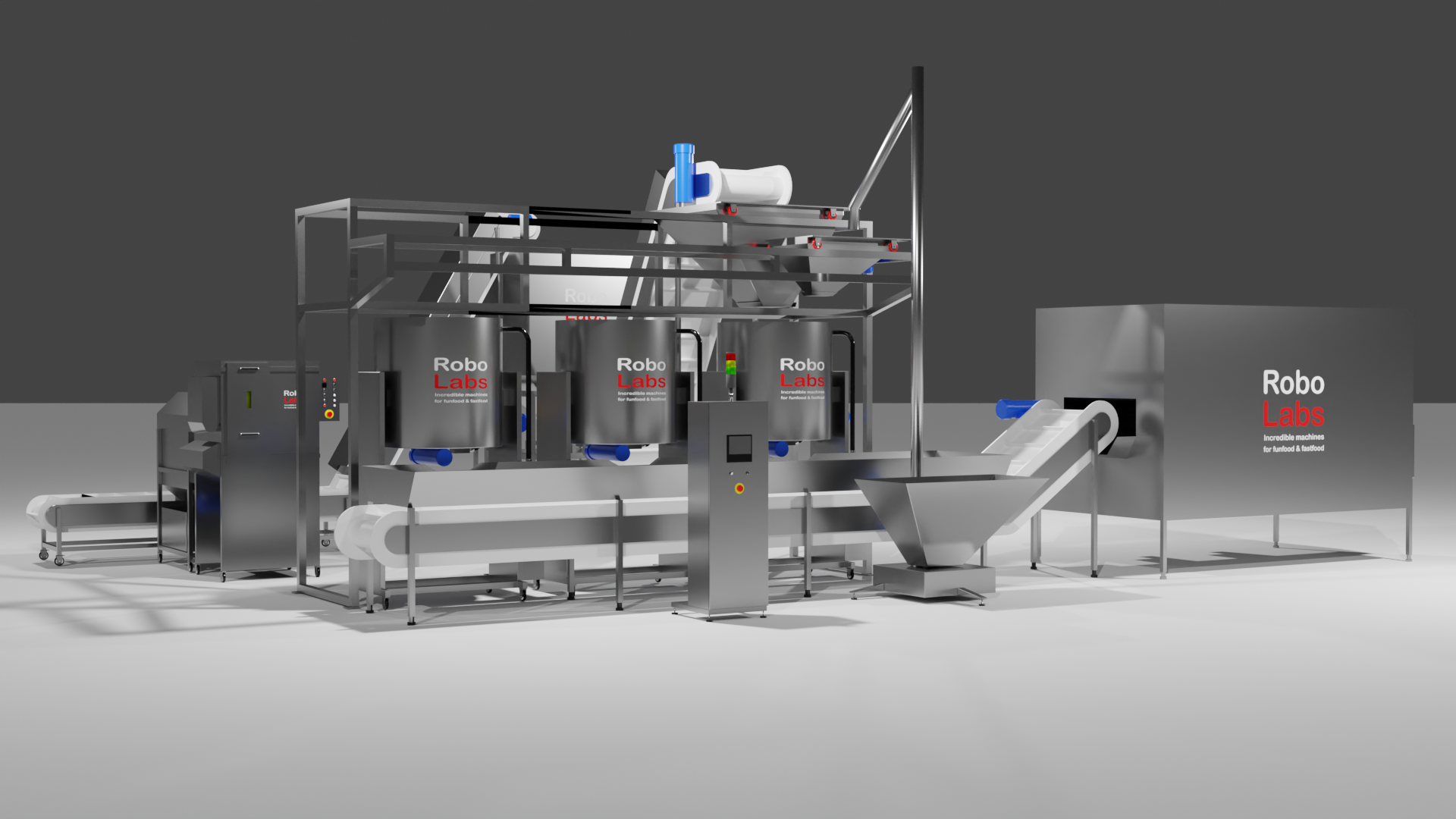

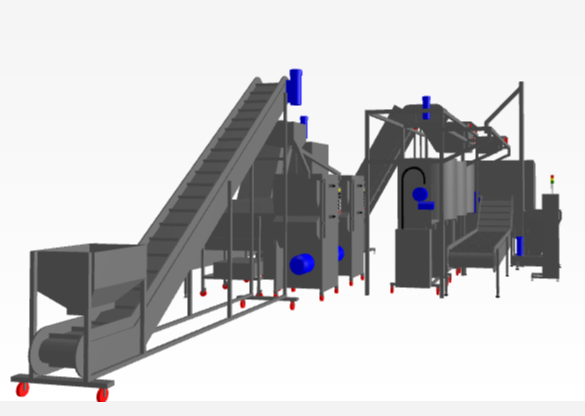

RoboFactory 200 is a turnkey cheesy/savory popcorn factory with a capacity of up to 200kg (440lbs) of popcorn per hour.Let’s buy

At the entrance, you pour raw materials: popcorn grains, salt, butter, cheese powder, and spices. As a result, you get the finished product without any extra effort.

The production line is fully automated, controlled from a single touchscreen, 1 operator is enough for maintenance. Each element of the line is displayed as a block on the touchscreen - starting, stopping, and changing settings done with a finger-press on the touch screen. All elements also have a backup control channel, which increases the reliability of the system as a whole.

Using the Robopop220 vortex popcorn machine allows you to refuse the "wet method" of opening the maize kernels - popcorn grains are not fried in oil (there are no trans fats or carcinogens). The product is healthier and less high-calorie.

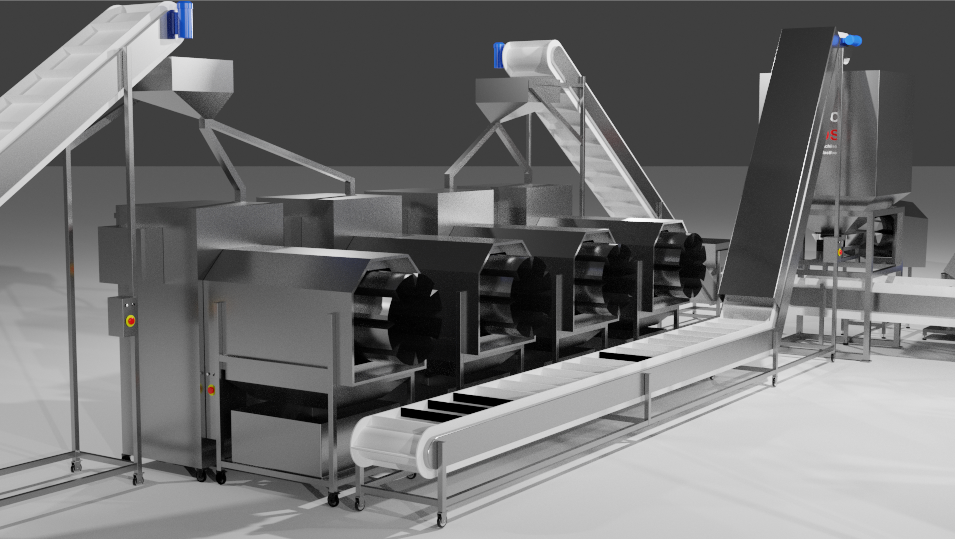

The oil is used only at the last stage to give the taste of the finished product, which also allows you to significantly reduce the cost and save on oil. Your premises will be cleaner - no need to remove oil cinders from the surfaces of equipment, cabinets, or floors. It is much easier to clean the popcorn equipment at the end of the shift.Product supportsRoboFactory 300 kg Salty/Cheese/Spicy Popcorn

Advantages- Highly automated - one touch screen

- Duplication of controls on each element

- Highly reliable

- Maintainability

- AISI304 food-grade stainless steel

- Easy to control - the entire line as modules on the touchscreen, and the settings of each module are easy to see and adjust Protection against misuse - the RoboFactory 300 is equipped with sensors and a sound / light alarm system that reports abnormal operating modes

- RoboFactory 300 is a turnkey cheesy/savory popcorn factory with a capacity of up to 100kg (220lbs) of popcorn per hour.

RoboFactory 300 es una fábrica llave en mano de palomitas de maíz condimentadas/con queso con una capacidad de hasta 300 kg (660 lbs.) de palomitas por hora. En la entrada se vierten las materias primas: granos de palomitas, sal, mantequilla, queso en polvo y especias. Como resultado, obtendrá el producto acabado sin ningún esfuerzo adicional.Let’s buy

La línea de producción está totalmente automatizada, se controla desde una única pantalla táctil, 1 operario es suficiente para el mantenimiento. Cada elemento de la línea se muestra como un bloque en la pantalla táctil: iniciar, detener y cambiar los ajustes se hace pulsando con el dedo en la pantalla táctil. Todos los elementos disponen además de un canal de control de reserva, lo que aumenta la fiabilidad del sistema en su conjunto.

El uso de la máquina de vórtice para producir palomitas Robopop220 permite rechazar el "método húmedo" de apertura de los granos de maíz: los granos de palomitas no se fríen en aceite (no hay grasas trans ni carcinógenos). El producto es más sano y menos calórico. El aceite sólo se utiliza en la última fase para dar el sabor del producto acabado, lo que también permite reducir considerablemente el coste y ahorrar en aceite. Sus instalaciones estarán más limpias: no tendrá que retirar las cenizas de aceite de las superficies de los equipos, armarios o suelos. Es mucho más fácil limpiar el equipo de palomitas al final del turno.Product supportsRoboFactoy 400 kg Salty/Cheese/Spicy Popcorn

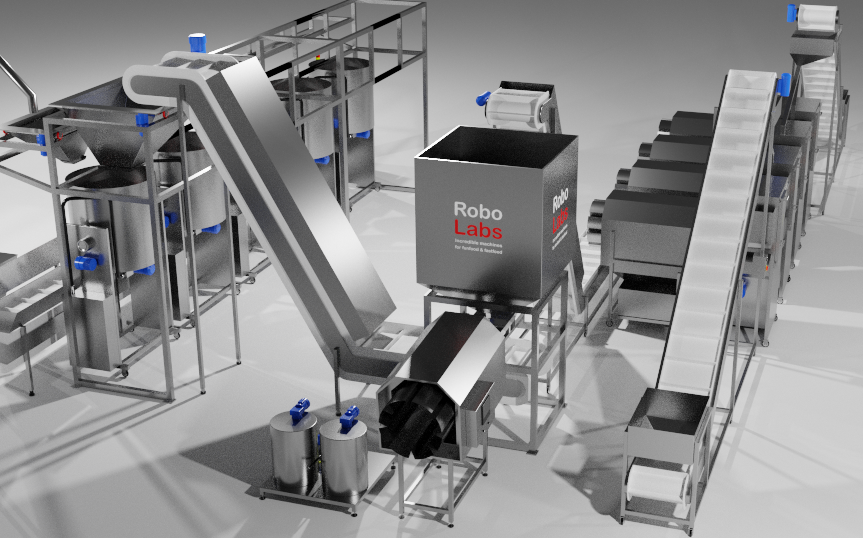

Advantages- Highly automated - one touch screen

- Duplication of controls on each element

- Highly reliable

- Maintainability

- AISI304 food-grade stainless steel

- Easy to control - the entire line as modules on the touchscreen, and the settings of each module are easy to see and adjust Protection against misuse - the RoboFactory 400 is equipped with sensors and a sound / light alarm system that reports abnormal operating modes

- RoboFactory 400 is a turnkey cheesy/savory popcorn factory with a capacity of up to 100kg (220lbs) of popcorn per hour.

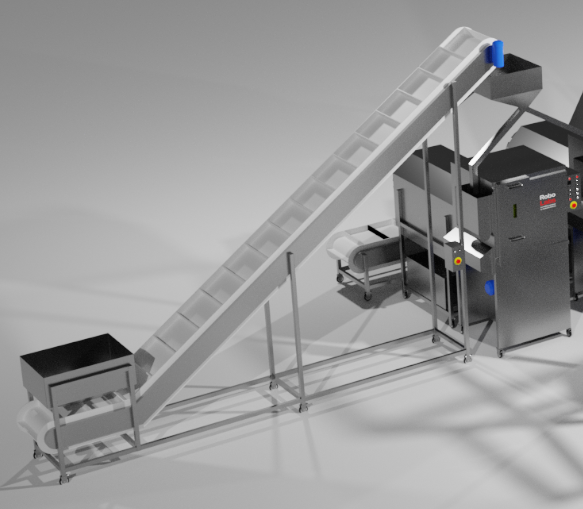

RoboFactory 400 is a turnkey cheesy/savory popcorn factory with a capacity of up to 400kg (880lbs) of popcorn per hour. At the entrance, you pour raw materials: popcorn grains, salt, butter, cheese powder, and spices. As a result, you get the finished product without any extra effort.Let’s buy

Presentation on Robofactory Popcorn lines: Download

The production line is fully automated, controlled from a single touchscreen, 1 operator is enough for maintenance. Each element of the line is displayed as a block on the touchscreen - starting, stopping, and changing settings done with a finger-press on the touch screen. All elements also have a backup control channel, which increases the reliability of the system as a whole.

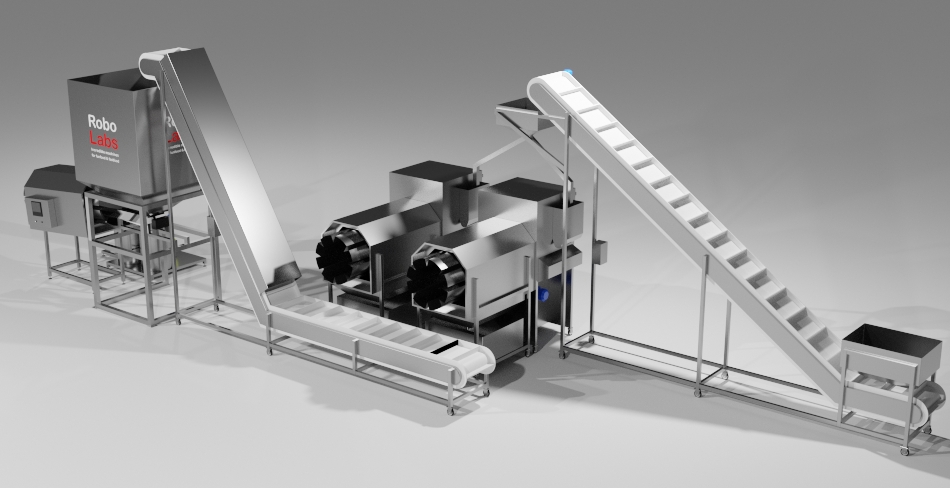

Using the Robopop220 vortex popcorn machine allows you to refuse the "wet method" of opening the maize kernels - popcorn grains are not fried in oil (there are no trans fats or carcinogens). The product is healthier and less high-calorie. The oil is used only at the last stage to give the taste of the finished product, which also allows you to significantly reduce the cost and save on oil. Your premises will be cleaner - no need to remove oil cinders from the surfaces of equipment, cabinets, or floors. It is much easier to clean the popcorn equipment at the end of the shift.RoboFactory 200 kg/h Caramel Popcorn

Advantages- Highly automated - one touch screen

- Duplication of controls on each element

- Maintainability AISI304 food-grade stainless steel

- Easy to control - the entire line as modules on the touchscreen, and the settings of each module are easy to see and adjust

- Protection against misuse - the RoboFactory 200 is equipped with sensors and a sound / light alarm system that reports abnormal operating modes

- Convenient boiler cleaning system of caramelizers SugarLips100

- Automatic feeding of dry ingredients into caramelizers

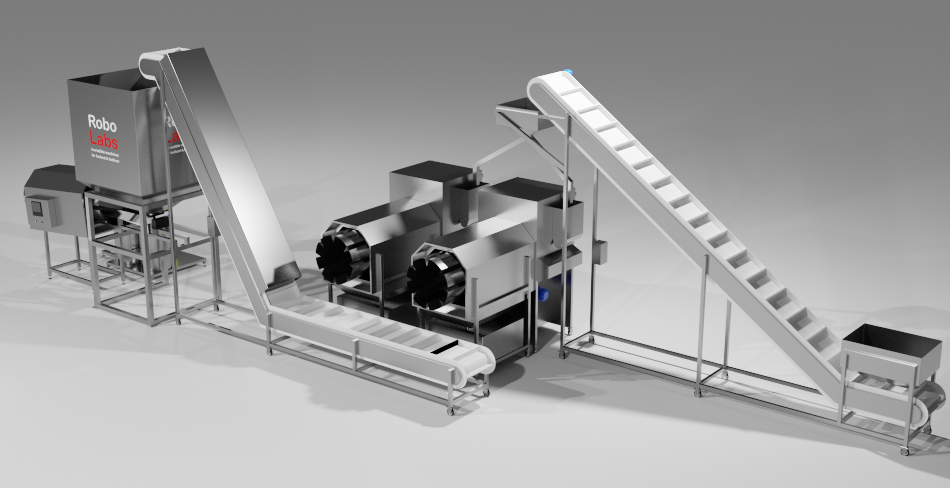

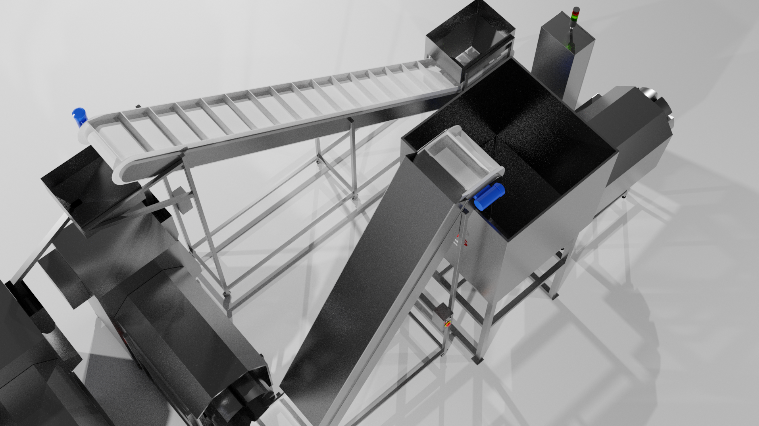

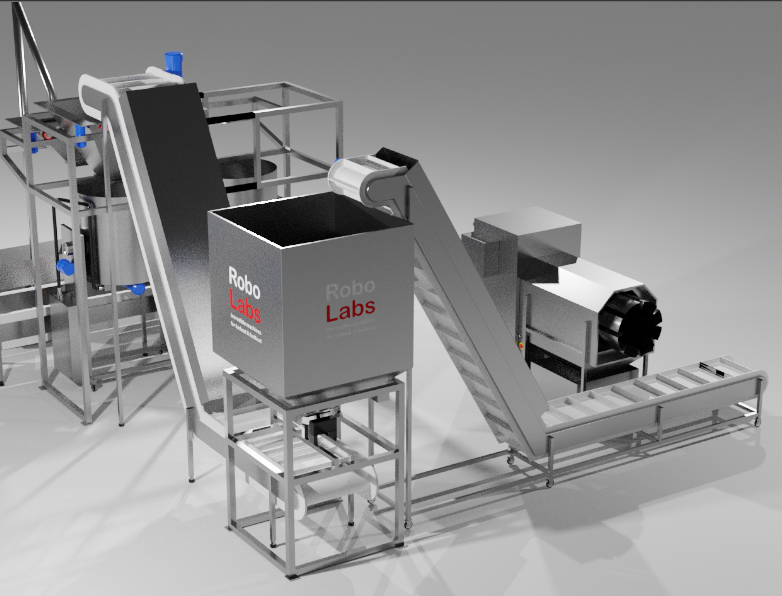

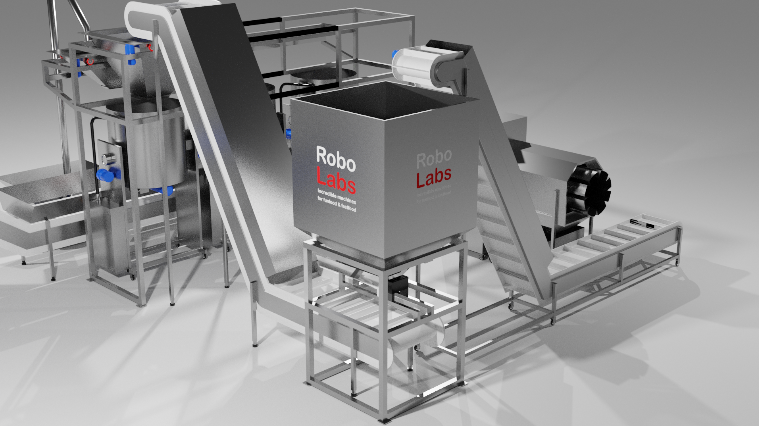

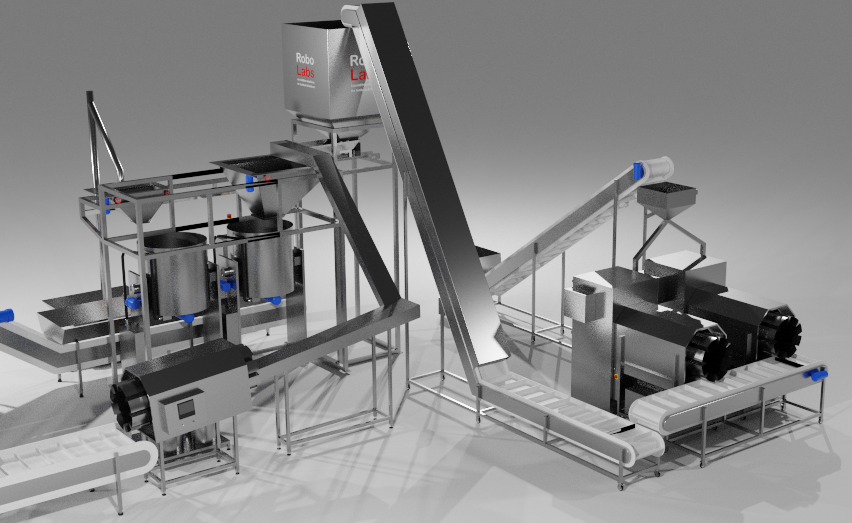

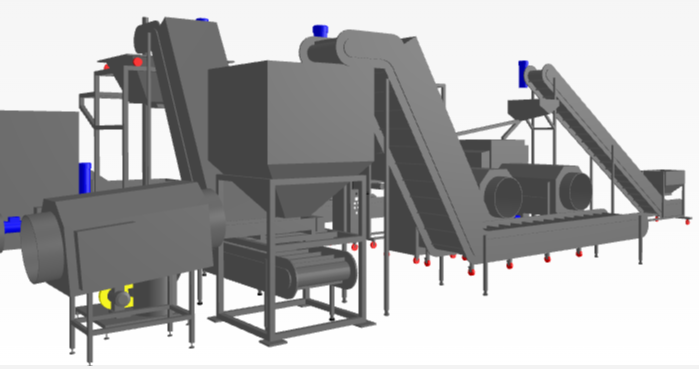

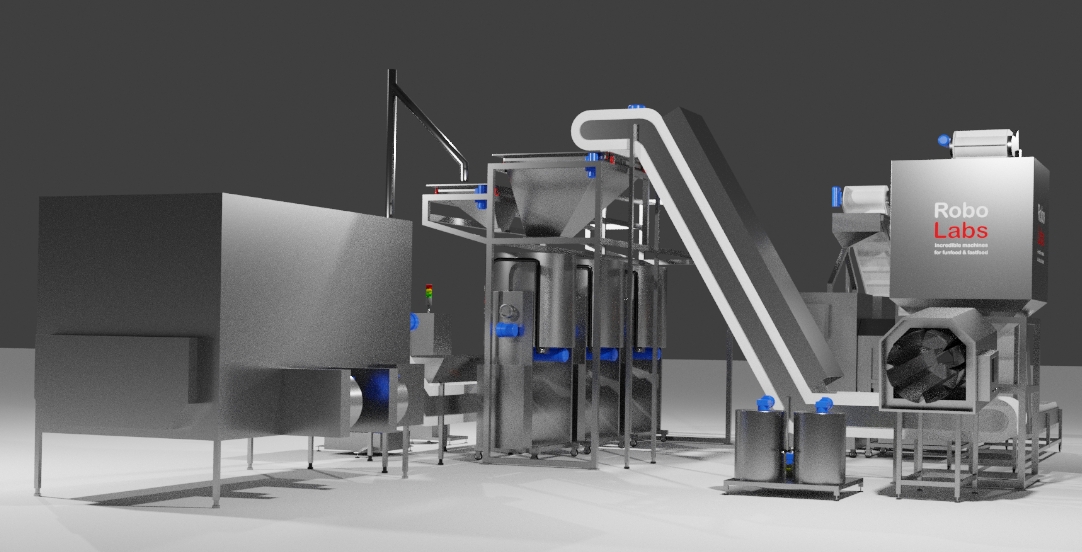

RoboFactory 200 for caramel popcorn is an automated solution for the production of gourmet popcorn in caramel, chocolate, and fruit flavors (strawberry, raspberry, blue raspberry, green apple, banana, orange, and so on). Production capacity - up to 200 kg (440 pounds) of popcorn per hour.Let’s buy

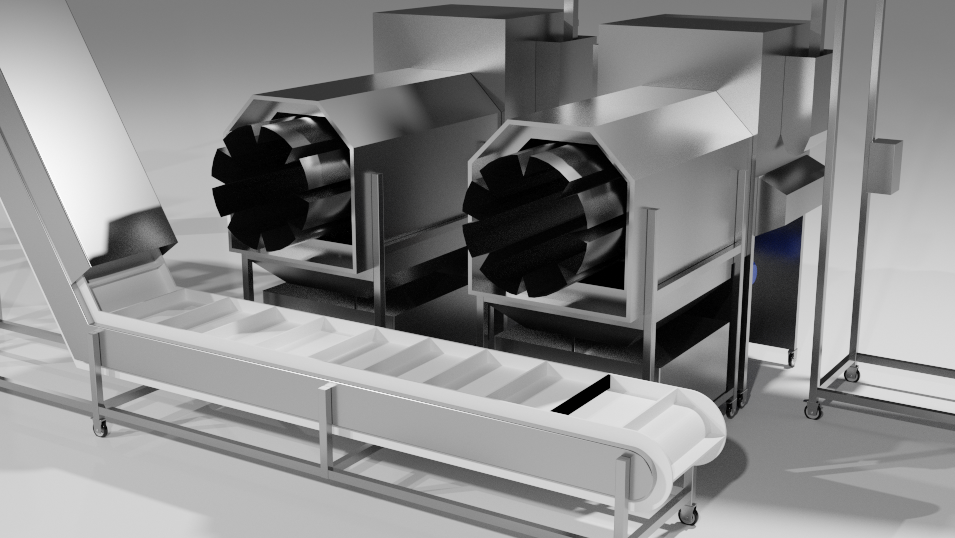

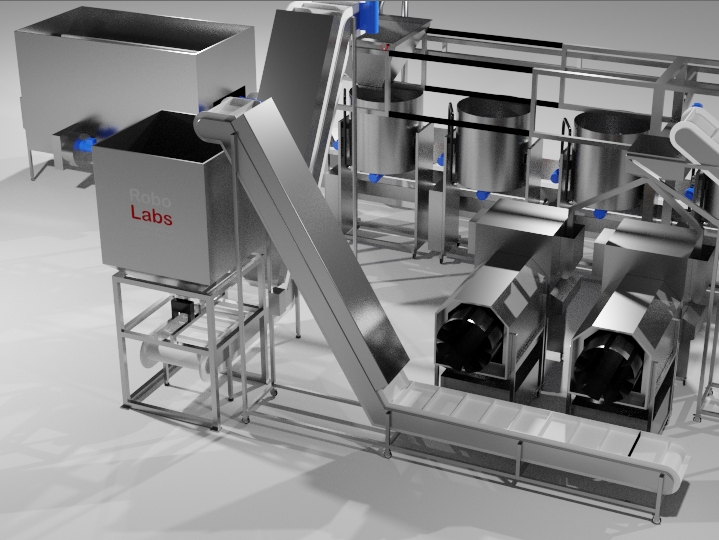

The line uses one Robopop220 to produce oil-free mushroom popcorn. After opening the grain, it is fed alternately into SugarLips100 caramelizing boilers (2 pcs). It is worth noting that the coating with heavy caramel increases the weight of the popcorn, so even 1 Robopop220 is enough for 2-3 boilers of SugarLips100.

The entire mini factory is controlled by one touchscreen. The processes are automated as much as possible - one operator is required to service the popcorn line.

Using the Robopop220 vortex popcorn machine can significantly reduce oil costs and increase system performance. The product is less high-calorie, and does not contain trans fats and carcinogens. Separation and cooling of popcorn take place in a giant separator, which also acts as a sifter - all small particles, broken popcorn, and husks are sieved through the holes of the separator.

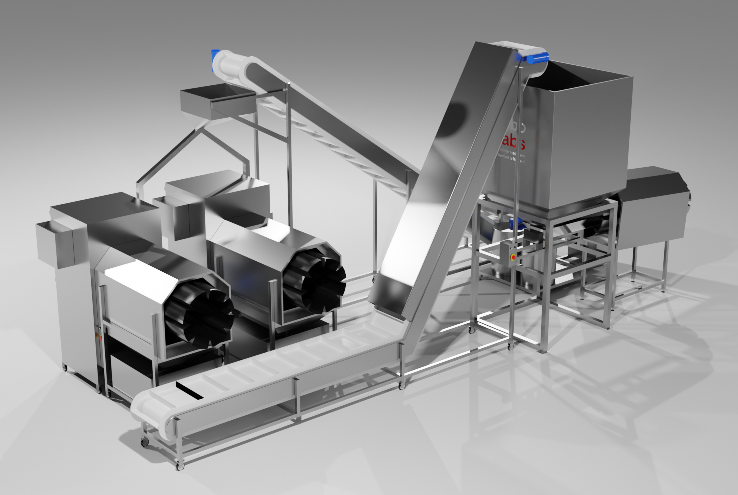

The line requires a supply of cold water and sewerage.In actionReviewsRoboFactory 300 kg/h Caramel Popcorn

Advantages- Highly automated - one touch screen

- Duplication of controls on each element

- Maintainability AISI304 food-grade stainless steel

- Easy to control - the entire line as modules on the touchscreen, and the settings of each module are easy to see and adjust

- Protection against misuse - the RoboFactory 300 is equipped with sensors and a sound / light alarm system that reports abnormal operating modes

- Convenient boiler cleaning system of caramelizers SugarLips100

- Automatic feeding of dry ingredients into caramelizers

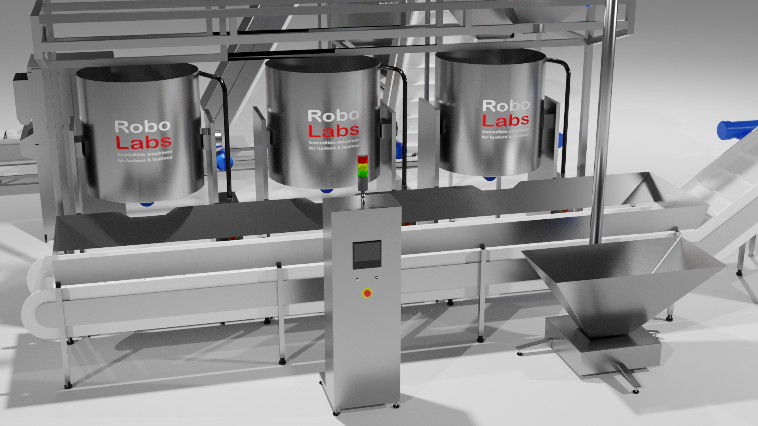

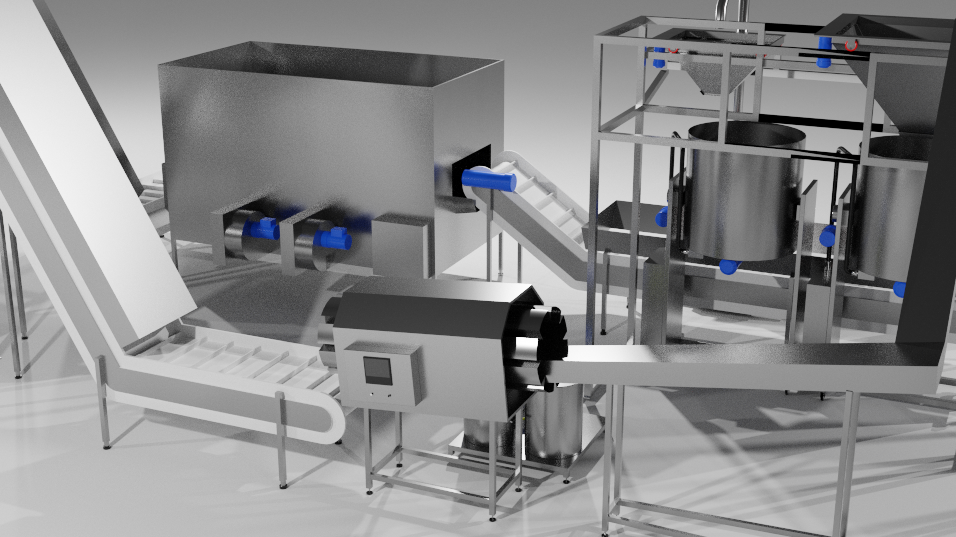

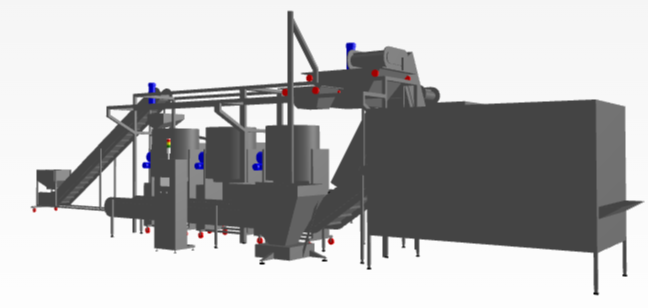

RoboFactory 300 for caramel popcorn is an automated solution for the production of gourmet popcorn in caramel, chocolate, and fruit flavors (strawberry, raspberry, blue raspberry, green apple, banana, orange, and so on). Production capacity - up to 300 kg (660 pounds) of popcorn per hour.Let’s buy

The line uses one Robopop220 to produce oil-free mushroom popcorn. After opening the grain, it is fed alternately into SugarLips100 caramelizing boilers (3 pcs). It is worth noting that the coating with heavy caramel increases the weight of the popcorn, so even 1 Robopop220 is enough for 2-3 boilers of SugarLips100. The entire mini factory is controlled by one touchscreen. The processes are automated as much as possible - one operator is required to service the popcorn line.

Using the Robopop220 vortex popcorn machine can significantly reduce oil costs and increase system performance. The product is less high-calorie and does not contain trans fats and carcinogens. Separation and cooling of popcorn take place in a giant separator, which also acts as a sifter - all small particles, broken popcorn, and husks are sieved through the holes of the separator. The line requires a supply of cold water and sewerage.RoboFactory 500 kg/h Caramel Popcorn

Advantages- Highly automated - one touch screen

- Duplication of controls on each element

- Maintainability AISI304 food-grade stainless steel

- Easy to control - the entire line as modules on the touchscreen, and the settings of each module are easy to see and adjust

- Protection against misuse - the RoboFactory 500 is equipped with sensors and a sound / light alarm system that reports abnormal operating modes

- Convenient boiler cleaning system of caramelizers SugarLips100

- Automatic feeding of dry ingredients into caramelizers

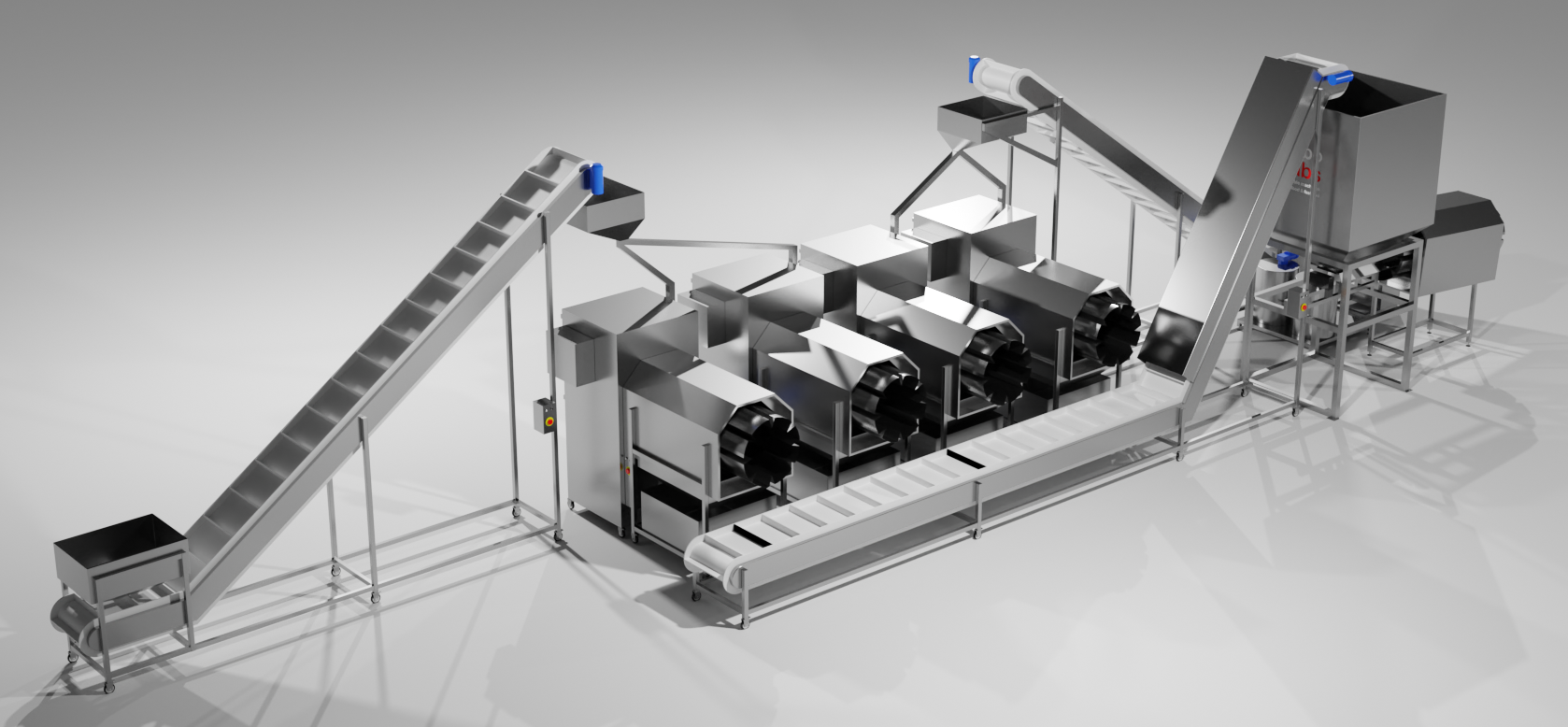

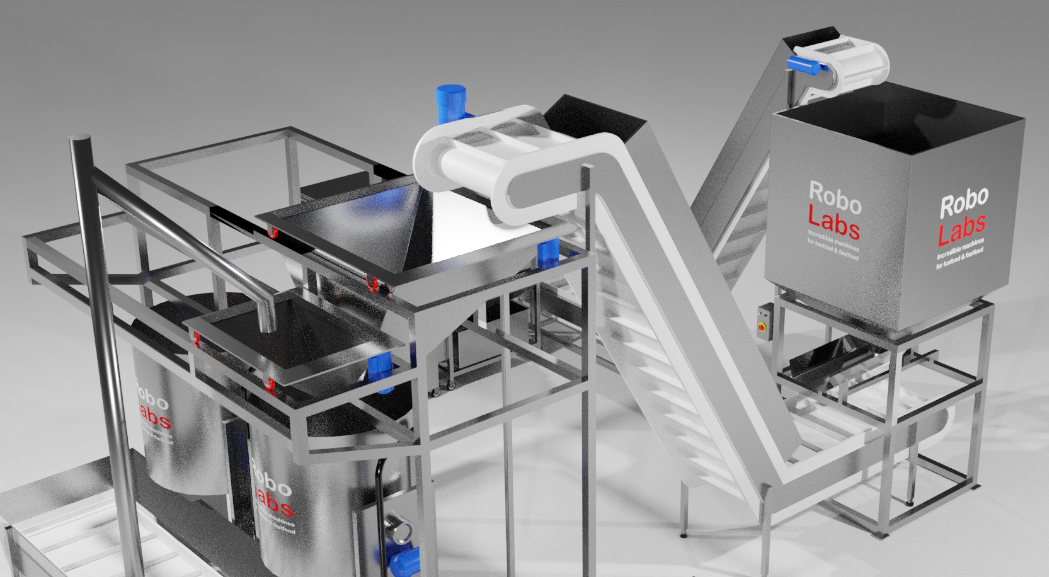

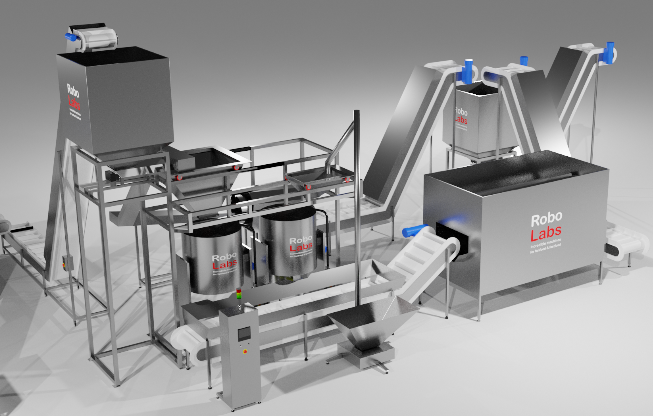

RoboFactory 500 for caramel popcorn is an automated solution for the production of gourmet popcorn in caramel, chocolate, and fruit flavors (strawberry, raspberry, blue raspberry, green apple, banana, orange, and so on). Production capacity - up to 500 kg (1100 pounds) of popcorn per hour.Let’s buy

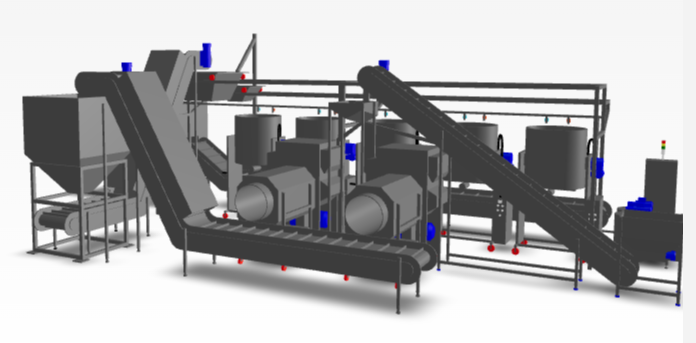

The line uses two Robopop220 poppers to produce oil-free mushroom popcorn. After opening the grain, it is fed alternately into SugarLips100 caramelizing boilers (5 pcs). It is worth noting that the coating with heavy caramel increases the weight of the popcorn, so even 2 Robopop220 is enough for 5 boilers of SugarLips100.

The entire mini factory is controlled by one touchscreen. The processes are automated as much as possible - one operator is required to service the popcorn line.

Using the Robopop220 vortex popcorn machine can significantly reduce oil costs and increase system performance. The product is less high-calorie and does not contain trans fats and carcinogens.

Separation and cooling of popcorn take place in a giant separator, which also acts as a sifter - all small particles, broken popcorn, and husks are sieved through the holes of the separator.

The line requires a supply of cold water and sewerage.RoboFactory 200 kg Salty & 200 kg Caramel Popcorn

Advantages- Highly automated - one touch screen

- Duplication of controls on each element

- Maintainability AISI304 food-grade stainless steel

- Easy to control - the entire line as modules on the touchscreen, and the settings of each module are easy to see and adjust

- Protection against misuse - the RoboFactory 200 is equipped with sensors and a sound / light alarm system that reports abnormal operating modes

- Convenient boiler cleaning system of caramelizers SugarLips100

- Automatic feeding of dry ingredients into caramelizers

- Popcorn production is based on innovative Vortex Popcorn popping technology which saves up to 60 kg of oil per hour (400 tons per year) vs. conventional hot oil popping.

- The line is fully automated. Ingredients are supplied automatically.

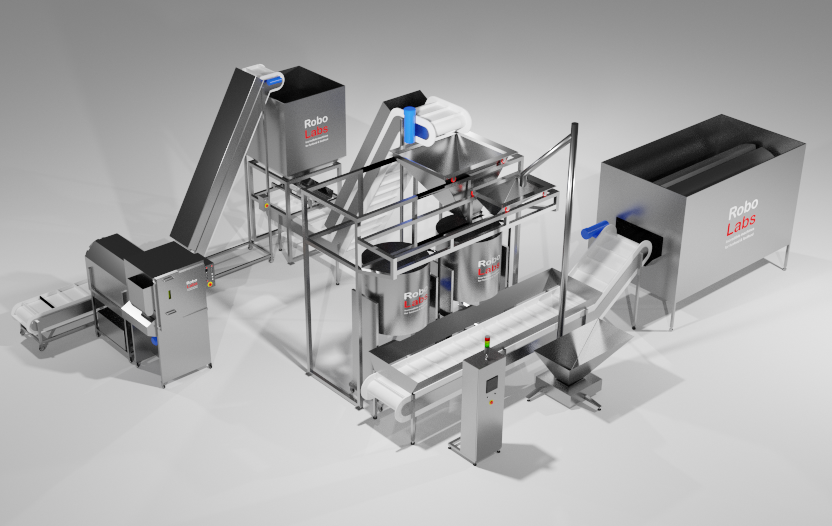

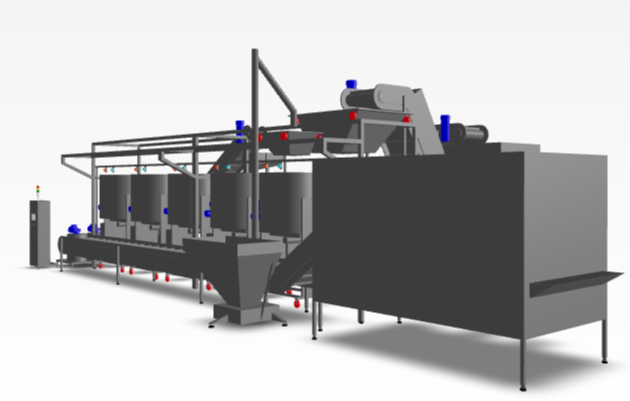

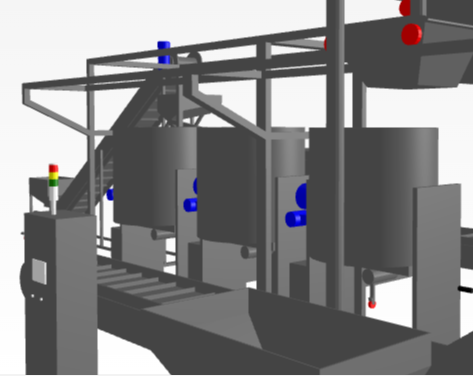

Industrial Salt+Caramel Popcorn Production Line with capacity up to 200kg/h of salt and up to 200kg/h of caramel popcorn.Let’s buy

Popcorn production is based on innovative Vortex Popcorn popping technology which saves up to 60 kg of oil per hour (400 ton per year) vs. conventional hot oil popping.

The line is fully automated. Ingredients are supplied automatically.

Separation and cooling of coated popcorn goes on in the cooling drum.

The line requires only one operator and one maintenance worker.

The Kettles are cleaned by automatic steaming.RoboFactory 200 kg Salty & 300 kg Caramel Popcorn

Advantages- Highly automated - one touch screen

- Duplication of controls on each element

- Maintainability AISI304 food-grade stainless steel

- Easy to control - the entire line as modules on the touchscreen, and the settings of each module are easy to see and adjust

- Protection against misuse - the RoboFactory 200 is equipped with sensors and a sound / light alarm system that reports abnormal operating modes

- Convenient boiler cleaning system of caramelizers SugarLips100

- Automatic feeding of dry ingredients into caramelizers

- Popcorn production is based on innovative Vortex Popcorn popping technology which saves up to 60 kg of oil per hour (400 tons per year) vs. conventional hot oil popping.

- The line is fully automated. Ingredients are supplied automatically.

Industrial Salt+Caramel Popcorn Production Line with capacity up to 200kg/h of salt and up to 300kg/h of caramel popcorn.Let’s buy

Popcorn production is based on innovative Vortex Popcorn popping technology which saves up to 60 kg of oil per hour (400 ton per year) vs. conventional hot oil popping.

The line is fully automated. Ingredients are supplied automatically.

Separation and cooling of coated popcorn goes on in the cooling drum.

The line requires only one operator and one maintenance worker.

The Kettles are cleaned by automatic steaming.Product supportsRoboFactory 400 kg Salty & 500 kg Caramel Popcorn

Advantages- Highly automated - one touch screen

- Duplication of controls on each element

- Maintainability AISI304 food-grade stainless steel

- Easy to control - the entire line as modules on the touchscreen, and the settings of each module are easy to see and adjust

- Protection against misuse - the RoboFactory 500 is equipped with sensors and a sound / light alarm system that reports abnormal operating modes

- Convenient boiler cleaning system of caramelizers SugarLips100

- Automatic feeding of dry ingredients into caramelizers

- Popcorn production is based on innovative Vortex Popcorn popping technology which saves up to 60 kg of oil per hour (400 tons per year) vs. conventional hot oil popping.

- The line is fully automated. Ingredients are supplied automatically.

Industrial Salt+Caramel Popcorn Production Line with capacity up to 200kg/h of salt and up to 300kg/h of caramel popcorn.Let’s buy

Popcorn production is based on innovative Vortex Popcorn popping technology which saves up to 60 kg of oil per hour (400 ton per year) vs. conventional hot oil popping.

The line is fully automated. Ingredients are supplied automatically.

Separation and cooling of coated popcorn goes on in the cooling drum.

The line requires only one operator and one maintenance worker.

The Kettles are cleaned by automatic steaming.Product supportsIn action

Presentation on Robofactory Popcorn lines: Download